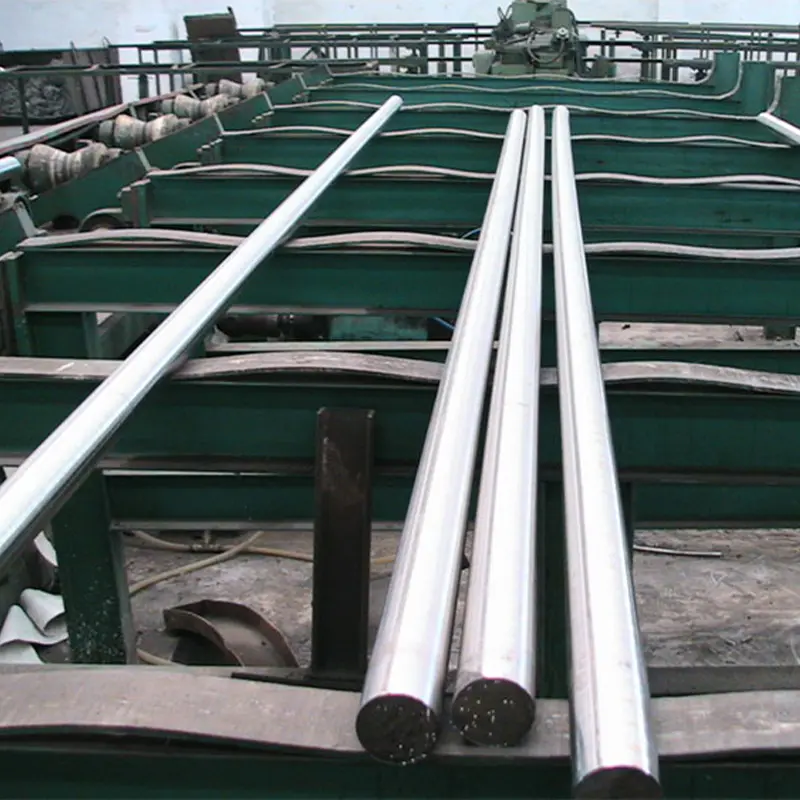

In the hot rolling process, stainless steel billets are heated above their recrystallization temperature (typically over 900°C) and passed through rollers to shape them into round bars. The high temperatures allow the steel to be easily molded and stretched into different dimensions, providing a ductile product that is ideal for applications that require material to undergo further processing, such as bending or forming. While hot-rolled Stainless Steel Round Bars exhibit enhanced workability and formability, they tend to have a rough, uneven surface and the grain structure aligns with the direction of rolling. This results in a less aesthetic appearance compared to cold-drawn bars, but it offers the advantage of being more flexible in terms of shaping, making them suitable for structural components, construction materials, and machinery parts where surface finish and precise dimensions are not the primary concerns. Hot-rolled bars are used in applications that are less demanding in terms of mechanical properties but where overall strength and cost-effectiveness are critical.

Cold drawing involves pulling stainless steel round bars through a die at room temperature. The material undergoes strain hardening as it is drawn through the die, which results in increased strength, hardness, and a smoother, more precise surface finish. Unlike hot-rolled bars, cold-drawn Stainless Steel Round Bars are typically used in applications requiring high precision, superior surface quality, and tighter dimensional tolerances. This process makes the bars less ductile compared to hot-rolled options, but they offer far greater strength and are better suited for applications that involve high-stress environments, such as aerospace, automotive, and precision engineering. Cold-drawn bars have enhanced fatigue resistance, creep resistance, and wear resistance, which make them ideal for parts that need to maintain their structural integrity under significant loading or thermal cycling conditions.

The mechanical properties of Stainless Steel Round Bars differ significantly between hot-rolled and cold-drawn methods. Cold-drawn bars typically exhibit higher tensile strength, yield strength, and hardness due to the strain hardening effect, making them ideal for high-performance applications where the materials are subject to continuous stress or need to withstand abrasion. Hot-rolled bars, on the other hand, have lower tensile strength and hardness but are more malleable, allowing them to be easily shaped for general applications. The grain structure of cold-drawn bars is more refined, resulting in better structural integrity over time, whereas the grain orientation of hot-rolled bars can lead to lower fatigue resistance, making them less suitable for high-cycle applications. Therefore, cold-drawn bars are preferred when high precision and strength are crucial, while hot-rolled bars are more appropriate for general-purpose uses where ease of fabrication and material flexibility are required.

The grain structure of Stainless Steel Round Bars plays a significant role in determining their strength and durability. Hot-rolled bars have a coarser grain structure due to the elevated temperatures during the rolling process. While this makes the material easier to work with and allows it to withstand deformation, the larger grain structure can reduce its fatigue resistance and creep resistance under extreme conditions, such as high temperatures or long-term loading. In contrast, cold-drawn bars have a finer grain structure, which results in enhanced strength, durability, and resilience under stress.

English

English русский

русский Español

Español عربى

عربى